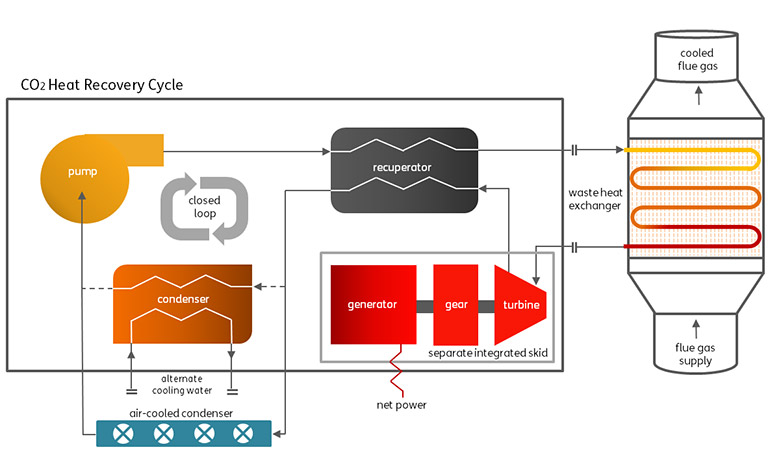

The EPS heat engine uses industrial grade liquid CO2 as the working fluid, which does not have practical temperature or pressure working limits.

The turbomachinery pumps the liquid CO2 to high pressure and passes through a combination of recuperators and waste heat exchangers (without using a secondary oil loop) before entering the turbo-expander, which drives the shaft that in turn drives a generator.

Effluent CO2 exits the turbine, and passes through a series of recuperators to exchange more heat, and finally enters the condenser where it is converted back to liquid CO2.

Exiting the condenser, the liquid CO2 re-enters the pump to repeat the cycle.

Now that you know the science behind the technology, it's time to see how it can benefit your business. Give us a call today at 234.542.4379 or fill out the contact form on this page for more information.